Prevent Motor Overheating: Common Causes & Solutions

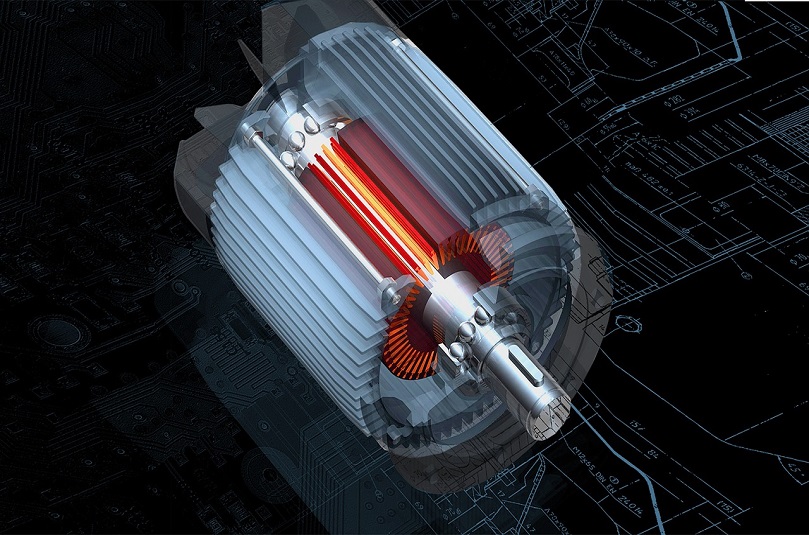

Electric motors are crucial parts of a vast array of industrial and home appliances. They work to transform electrical energy into mechanical energy and are employed to drive conveyors, pumps and other devices. Electric motors can damage themselves and lose efficiency when they overheat, too. In this article, we will discuss the causes of electric motor overheating and the steps that can be taken to prevent it.

Causes of Electric Motor Overheating

Major causes of electric motor overheating are:

1. Overloading

One of the most common causes of electric motor overheating is overloading. This occurs when the motor is required to operate at a load that exceeds its rated capacity. As a result, the motor must exert more effort to do the same duty which increases heat generation and increases the risk of damage. Make sure the motor is the appropriate size for the equipment it is powering and that the load is not excessive to prevent overloading.

2. Insufficient ventilation

Inadequate ventilation is a typical cause of electric motor overheating. As they run, electric motors produce heat which needs to be removed to avoid damage. The engine will overheat if the heat is not properly dissipated from it. Make sure the motor is installed in a well-ventilated space and that there is enough airflow around it to avoid this.

3. Dirty or clogged air filters

Overheating of an electric motor can also be brought on by dirty or clogged air filters. Dust, dirt and other pollutants can be taken out of the air with the use of the air filters in the motor’s ventilation system. Reduced airflow and greater heat buildup will result from the filters’ inability to properly remove these impurities if they become clogged. Make sure the air filters are changed or cleaned frequently to avoid this.

4. Bearing failure

Another frequent reason for electric motor overheating is bearing failure. The rotor is supported by and can rotate smoothly thanks to bearings. Increased friction and heat production will result from the bearings’ inability to support the rotor correctly if they are worn out or broken. Make sure the bearings are properly greased and inspected frequently to avoid bearing failure.

5. Incorrect voltage

Overheating can occur when the incorrect voltage is applied to an electric motor. The motor may work harder than it was intended to if the voltage supplied is too high or too low increasing heat generation and perhaps causing damage. Make sure the motor is connected to the proper voltage source and that the voltage is stable and within the manufacturer-specified range to avoid this.

6. High ambient temperatures

Electric motor overheating can also be brought on by high ambient temperatures. The heat produced by the engine may be increased and cause overheating if it is situated in a warm area such as a factory or warehouse. Make sure the motor is placed in a cooler region to avoid this or utilize cooling techniques like fans or air conditioning to remove heat.

7. Wiring issues

Overheating of an electric motor can also be brought on by wiring problems. A loose, frayed or broken wire may cause poor electrical contact and higher resistance which could enhance the production of heat. To avoid this, make sure the wiring is connected correctly and in good shape. You should also routinely check for frayed or loose wires.

8. Mechanical issues

Mechanical issues such as misalignment or worn parts can also cause electric motor overheating. Greater friction and heat production can be caused by the motor’s rotor and stator being out of alignment, whilst increased resistance and heat production can be brought on by worn parts. Make sure the motor is correctly aligned and that all mechanical components are in good shape and receive regular maintenance to avoid this.

9. Poorly lubricated gears or bearings

A motor might overheat if the gears and bearings are not adequately maintained and face increased friction. Lack of lubrication can make the motor work harder and produce more heat because lubrication is crucial for decreasing friction and wear on moving parts. Make sure that gears and bearings are adequately oiled in accordance with the manufacturer’s instructions to avoid this.

10. Lack of maintenance

A lack of regular maintenance can also cause electric motor overheating. Over time, dirt and debris can accumulate on the motor reducing its efficiency and causing it to overheat. Additionally, worn or damaged parts can lead to increased resistance and heat generation. To prevent this, ensure that the motor is regularly inspected, cleaned and maintained according to the manufacturer’s recommendations.

11. Inefficient design

Electric motors that are poorly designed or manufactured can also experience overheating issues. The motor’s efficiency can decrease and it can overheat if dirt and debris are allowed to build up on it over time. Additionally, heat generation and higher resistance might be caused by worn or damaged parts. Make sure the motor is routinely inspected, cleaned and maintained in accordance with the manufacturer’s instructions to avoid this.

12. Overheating protection failure

Thermal guards or thermal cut-offs are common built-in overheating prevention systems for electric motors. The motor may overheat if these mechanisms malfunction, though. Make sure the protective systems are functional and consistently tested to avoid this.

In conclusion, electric motors are essential parts of many industrial and home appliances but they can overheat and cause damage if not properly maintained. Common causes of electric motor overheating include overloading, insufficient ventilation, dirty or clogged air filters, bearing failure, incorrect voltage, high ambient temperatures, wiring issues, mechanical issues, poorly lubricated gears or bearings, lack of maintenance, inefficient design and overheating protection failure. To prevent electric motor overheating, it is important to make sure the motor is the appropriate size for the equipment it is powering, ensure proper ventilation and airflow around the motor, frequently change or clean air filters, properly grease and inspect bearings, supply the correct voltage, place the motor in a cooler area or use cooling techniques, check for loose or frayed wires, maintain proper alignment and good condition of mechanical components, lubricate gears and bearings according to manufacturer’s instructions, regularly inspect, clean and maintain the motor according to manufacturer’s recommendations and test and maintain overheating protection systems.

Best Electrical Tapes for Outdoor Use: Buying Guide

Best Electrical Tapes for Outdoor Use: Buying Guide  What is an Arc Flash Relay? How Does it Work?

What is an Arc Flash Relay? How Does it Work?  What is a Dual Function Circuit Interrupter? And Its Function

What is a Dual Function Circuit Interrupter? And Its Function  Advantages and Disadvantages of Incandescent Lamps

Advantages and Disadvantages of Incandescent Lamps  VFD Parts: A Guide to Their Essential Functions

VFD Parts: A Guide to Their Essential Functions  Applications of 3-Phase Induction Motors in Industries

Applications of 3-Phase Induction Motors in Industries