Types of Soft Starters for Motors: Discover All

If you’re looking to reduce the wear and tear on your motor, improve energy efficiency and extend the lifespan of your equipment, a soft starter could be just what you need. But with so many different types of soft starters available on the market, it can be challenging to know which one is right for your specific application. In this article, we’ll take a closer look at the various types of soft starters for motors, so you can make an informed decision for your business.

Types of Soft Starters

Different styles of soft starters control the motor in different ways and offer different features. Some soft starter types are:

1. 1-phase controlled soft starter

When the terms 1-phase, 2-phase, or 3-phase ‘controlled soft starter’ is used, it refers to the number of sets of thyristors that are being used. 1 phase-controlled device has thyristors only in 1 phase.

The remaining phases are directly connected from line to load. 1 phase-controlled device reduces torque shock at the start but does not reduce start current. Also known as torque controllers, these devices must be used in conjunction with a direct online starter.

2. 2-phase controlled soft starter

2 phase-controlled devices have thyristors in 2 phases. The remaining phase is directly connected from line to load. These devices eliminate torque transients and reduce motor start current. The first thing noted when starting a 3-phase motor with a 2-phase controlled soft starter is that the currents in the phases are not equal. Typically, the controlled phases have approximately 30-50% lower current relative to the uncontrolled. When a compact and cost-effective solution is required 2 phase-controlled soft starters can be used. 2-phase soft starters can’t be used with an inside delta connection.

3. 3-phase controlled soft starter

These devices control all three phases, providing the optimum in soft start control. Three-phase control should be used for severe starting situations. In 3-phase controlled soft starters, all three phases will have 2 thyristors/phase. Here 3 phase current will be fully balanced when compared to 2-phase controlled devices. 3-phase soft starters can be connected inside delta.

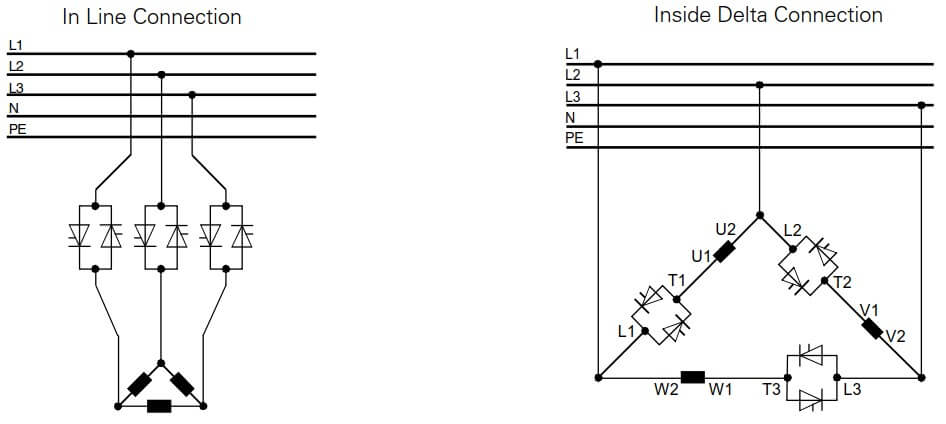

4. In-line connected soft starter

An in-line connection is the most common and also the easiest way to connect the soft starter. It’s also called direct connection. All three phases are connected in series with the overload relay, the main contactor, and other devices. The selected devices for an inline connection must be chosen to cope with the full-rated motor current. The motor itself can either be star-connected or delta-connected.

5. Inside delta connected soft starter

The inside delta connection makes it possible to place the soft starter in the delta circuit and allows for a very easy replacement of existing star-delta starters. When the soft starter is inside delta it will only be exposed to 58% of the Inline current. Therefore, it is possible to downsize the devices to achieve a more cost-effective solution.

A direct connection requires less output wiring than an inside delta connection, which requires double the wiring. On the other hand, the inside delta connection requires a smaller cross-section. Because of this, an inside delta connection will normally be a less expensive option for short distances, when considering the soft starter + motor + wiring.

A motor used for an Inside Delta connection must be able to delta-connect during a continuous run. In the USA and some other countries, a special six-wire motor has to be ordered for this type of connection.

6. Potentiometer-type soft starter

Potentiometer-type soft starters are generally basic soft starters. The set-up of the soft starter can easily be done and confirmed using marked potentiometers on the front.

7. Displayed type soft starter

Displayed type soft starters are advanced soft starters. The display and the button keypad make it easy to take advantage of all the advanced functionality in the soft starter. The display is used for several purposes such as programming the soft starter, i.e. setting up inputs and outputs, protection functions, warning levels, Fieldbus communication, etc. The display will also provide all the necessary information both during ramping and continuous operation.

8. Class 10 type soft starter – Normal start

The involved moment of inertia or flywheel mass is the size of the flywheel, connected to the motor axis. An application with a small moment of inertia is usually called a normal start. A normal start has a small moment of inertia and a short starting time. Normally OL class 10 is used. Examples of applications are pumps, compressors, bow thrusters, and short conveyor belts. You can select the soft starter size according to the motor kW ratings.

9. Class 30 type soft starter – Heavy-duty start

An application with a big moment of inertia is called a heavy-duty start. The heavy-duty start has a big moment of inertia and a long starting time. Normally OL class 30 is used. Examples of applications are fans, crushers, mills, and long conveyor belts. You can select a soft starter one size larger compared to the motor kW ratings.

In conclusion, using a soft starter for your motor can provide numerous benefits, including reducing wear and tear, improving energy efficiency, and extending the lifespan of your equipment. However, with so many different types of soft starters available, it can be challenging to choose the right one for your specific application. This article provides an overview of various types of soft starters, including 1-phase, 2-phase, and 3-phase controlled devices, in-line and inside delta connections, potentiometer-type and displayed type soft starters, and class 10 and class 30 types. By understanding the differences between these types of soft starters, you can make an informed decision to find the best solution for your business needs.

Best Electrical Tapes for Outdoor Use: Buying Guide

Best Electrical Tapes for Outdoor Use: Buying Guide  What is an Arc Flash Relay? How Does it Work?

What is an Arc Flash Relay? How Does it Work?  What is a Dual Function Circuit Interrupter? And Its Function

What is a Dual Function Circuit Interrupter? And Its Function  Advantages and Disadvantages of Incandescent Lamps

Advantages and Disadvantages of Incandescent Lamps  VFD Parts: A Guide to Their Essential Functions

VFD Parts: A Guide to Their Essential Functions  Applications of 3-Phase Induction Motors in Industries

Applications of 3-Phase Induction Motors in Industries